Article from:

Journal of Creation24(3):60–66

December 2010

Browse this issue

Subscribe to Journal of Creation

Recommended Resources

The Puzzle of Ancient Man

by Donald Chittick

Complete Works of Flavius Josephus, the Jewish Historian

by William Whiston, AM (Translator)

The Annals of the World

by James Ussher

How did they build the Great Pyramid?—an architect’s proposal

by Trevor Harrisa Many people are fascinated by the pyramids of Egypt. Why were they built? But more challenging—how did they do it? In particular with the Great Pyramid—how did they construct it to the enormous height with such accuracy and precision? By examining the pyramid through modern architectural eyes, assuming the builders had access to a reasonable level of technological skills, a certain solution suggests itself. A detailed analysis shows that such a solution is feasible and constructible, and even referred to within some ancient records.

wikimedia.org: Nina Aldin Thune

Figure 1. The Great Pyramid of Giza, also called the Pyramid of Khufu or the Pyramid of Cheops, is the only remaining wonder of the Seven Wonders of the Ancient World.

Most theories for the building of the Great Pyramid (figure 1) are derived from an evolutionary view of human history whereby primitive humans developed engineering and building construction by trial and error over many millennia. Consequently, explanations and illustrations of pyramid construction often show a large army of grunting workers hauling huge blocks of stone up large ramps.

A different picture emerges when we assume biblical history. From this perspective the descendants of Noah formed the basis for all the early civilizations. Their advanced architectural forms and technologyshow the intelligence of these people. Examples can be found in the Middle East, China and the Americas.

These descendants inherited sophisticated engineering skills, obviously sufficiently developed in the building of the Ark that survived the Flood, and the Tower of Babel afterward (Genesis 6–9; 11). For example Mizraim, who was a grandson of Noah, was the patriarch of a tribe that settled in Egypt. In Egypt the earliest structures do exhibit experimentation, the development of craft skills and evidence of metallurgical processes. An iron plate (confirmed by chemical analysis in 1989) was found embedded in the Great Pyramid in 1836 by an assistant of explorer Colonel Vyse.1

The Great Pyramid

Most commentators acknowledge that the Great Pyramid of Giza in Egypt, also called the Pyramid of Khufu (or Cheops), demonstrates a massive increase in sophistication of design and complexity of construction. It is also one of the most accurately aligned structures to true polar north. The reason for this earlier complexity has been difficult to explain from the traditional evolutionary perspective.

The Great Pyramid is a high point in construction techniques. The Pyramid of Khafre adjacent, built later, is a close but very poor copy, and most subsequent pyramids are even more inferior. Thus pyramid construction degenerated with time rather than improved, pointing to a devolution of design and construction techniques.

The Great Pyramid is the only one of the Seven Wonders of the Ancient World that has survived to this day. It is the most measured and surveyed building in the world and has generated the most debate about its original measurements and their meaning. No evidence has been found of Egyptian hieroglyphs, idols or coffin remains in the structure. However there are some graffiti examples in some parts of the upper chambers. It is accepted by most to have been built in the 4th Dynasty reign of Pharaoh Khufu.2 However there is debate about the dating of this dynasty and whether he is the main instigator.

The height and volume

The Great Pyramid currently measures 138 m high which is the equivalent of a 46 storey building. It was the tallest structure that humans had erected until the building of the Lincoln Cathedral spire (UK) at 160 m in AD 1311 (over 3,500 years later).

It is just under half the height of the Eiffel Tower (300 m to its roof) built in 1888. It is close to half the height of Australia’s 3 highest structures: Sydney’s Centre-point Tower (305 m), Melbourne’s Eureka Tower (297 m) and Gold Coast Q1 building (275 m). However, it would take exactly 6 Great Pyramids to reach the top of the current tallest building, Burj Khalifa (Dubai Tower), in the Middle East, which is 828 m high and was built in 2008.

The volume of the Pyramid would fill the Empire State Building in New York 2.5 times.

The volume of the Pyramid would fill the Empire State Building in New York 2.5 times.

Engineering requirements in construction

Rather than speculating on how such a great structure could have been built using primitive techniques, it is proposed how an intelligent ancient architect could design and build the structure with the technology of that era. There are a number of technical requirements for any proposal for the building of the Great Pyramid. These include:

A regular and fast rate for the delivery and placement of the estimated 2,300,000 stone blocks. The accepted time frame of construction is between 20–30 years. Some have proposed shorter periods with a required delivery rate of 3 stones per minute.

The 203 courses of masonry must be accurately leveled and the level must be maintained to accurate tolerances through the entire construction.

The slope angles of each corner of the pyramid must be accurately measured and the slope must be accurately maintained. Any deviations in slope would have a catastrophic effect as the level of the pyramid rose higher.

The slope face angles on each of the four sides needed to be accurately checked and maintained. This would have been critical for the placement of the limestone casing stones that covered each side.

There is debate about the materials used for the stone blocks. Some advance the idea that they were cast ‘polymer’ concrete (in situ). The conventional understanding is quarried stone. The casing stones and the chamber-forming blocks are large quarried stones. Either way, they represent large volumes of material and these large stone blocks had to be lifted to great heights.

Getting to the top

Photo: Egyptologist David Down

Figure 2. An example of a single stage ramp to the top of the pyramid, an unlikely scenario. This is in the Pharaonic Village in Cairo.

Many different proposals have been suggested to reach the height required. Most of these involve complicated ramps and do not meet the requirements listed above as they cover the critical sight survey lines.

A full ramp to the top at 138 m has a certain appeal, and such a ramp is illustrated in a model in the Egyptian Pharoanic Museum (figure 2). However, a ramp to the full height would be huge in scale and impractical. It would require much more material than the pyramid itself and involve an enormous effort to build and dismantle. It could not be built with sand or gravel as this would spread under its own weight. An engineered ramp of mudbrick would also be massive and not very feasible. Therefore, I have discounted the idea of a ramp to the full height.

The idea of an internal spiral tunnel by French architect J.P. Houdin and supported by archaeologist Bob Brier is another proposal aimed at getting a ramp to the top.3 This suggestion is impractical for many reasons, including the structural requirements of the pyramid. It would greatly weaken the structural integrity of the pyramid due to the massive forces resulting from forming the shape. It would not be practical from a logistical point of view, in that it would be difficult to haul 40- to 60-tonne stone blocks up through such a confined passage. The rate of stone delivery would be too slow with only one path for materials movement.

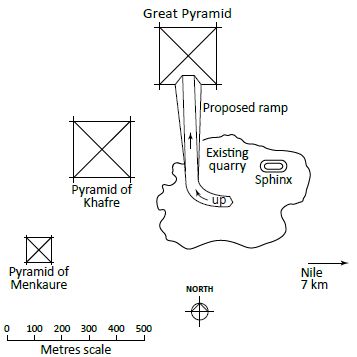

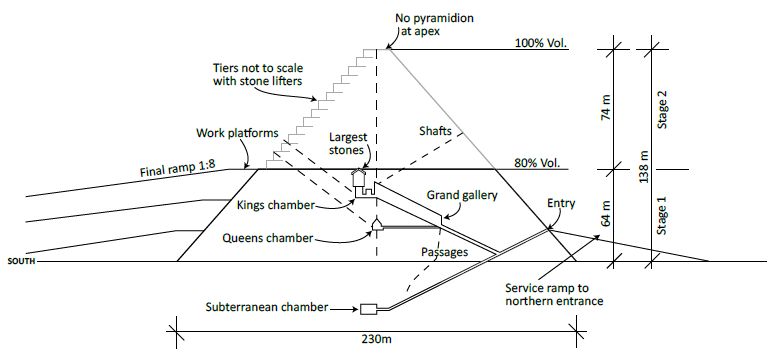

Figure 3. Site plan of the Giza Plateau showing the Great Pyramid, the Pyramid of Khafre and the Sphinx. The proposed southern construction ramp to the 64-metre level is shown extending from the quarry to the Great Pyramid. (After Romer, ref. 2, p. 14)

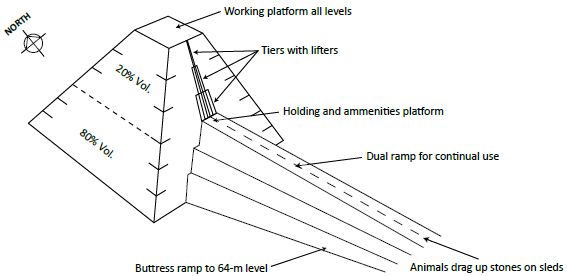

I propose that a two stage approach to the construction, that meets the engineering requirements listed above, successfully explains how they got to the top. The first stage involves a construction ramp to a critical level part way up. The second stage involves forming ‘tiered platforms’ in the structure to enable materials to be lifted for the upper levels.

Southern construction ramp—stage 1

It is proposed that the main construction ramp was on the south side of the pyramid (figure 3). The reasons for this include:

A ramp on the southern side would provide the shortest distance from the quarry to the Pyramid site, a key factor for the efficient delivery of such an enormous quantity of stone material. The source of most of the building stones is the large quarry 500 m to the south (figure 3).

Some evidence has been found of remains of a southern ramp.4

The eastern side has remains of a ramp but this was probably for the delivery of the casing stones (as discussed later). It is also the location side of what may be set-out lines for dimensional checking as proposed by John Romer.5

The northern side is discounted because it has the only entrance way into the structure.

Engineering restraints suggest the main ramp reached only part way up the pyramid. It is proposed that the ramp was only to the 64-metre level approximately, which is the level needed to raise the heaviest stones that were placed above the King’s Chamber (approximately 60 tonnes). From an engineering perspective, a ramp built to this level is practical and possible using simple construction materials and techniques such as battered (splayed) mud brick walls. This technique has been found at other pyramid sites but on a lesser scale.

The southern ramp would need to extend 512 m from the quarry to the pyramid, which means the maximum gradient reached at the 64-metre level would only be of 1:8 (64 m in 512 m, figure 4). This gradient is quite acceptable for people and animals to climb. Many modern-day car ramps are constructed to this gradient.

Figure 4. Concept of the dual construction ramp for the Great Pyramid to its maximum ramp height of 64 m.

What kind of ramp?

A ramp that allows for continual adjustment in height for each level is required as the work proceeds. Maintaining a continual rate of delivery of people and materials is a challenge. Given the logistics, a four lane carriageway would be ideal to ensure this. More lanes could be provided at the lower levels.

This structure could have been constructed as a ‘dual ramp’, which would permit a continuous delivery of materials to the pyramid even as the ramp was being built up. The design allows delivery of materials utilizing one side of the ramp while the other side of the ramp was being raised—then vice versa. Thus a continual flow of materials and workers can occur while the ramp structure is raised in tandem.

The building stones could be mounted on metal sleds at the quarry and then carted by animals the whole distance up the ramp, onto the stone platform and close to the required position.

This ramp could be made with materials readily available in the area. Mud bricks made on the banks of the Nile adjacent would be the bulk of the material. On the sides of the ramp they could be chambered (sloped) at a nominal 60 degrees to give stability. The volume as proposed is approximately 760,000 m3.

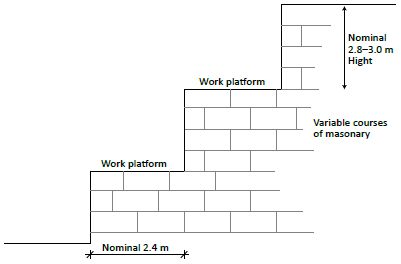

A working platform

Any large building site needs a large working area. The delivery of materials and amenities for workers must be near the works in progress. With the ramp proposal it allows a very large flat area at the top at each stage to give this function (figure 5).

Figure 5. North-south cross-section of the pyramid illustrating the two-stage construction method with construction ramp to the 64-metre level and stone lifters above. Also shown are some of the internal features of the pyramid, including the subterranean passageway.

As it rises, this platform narrows so it is important to establish the required platform for the second stage of the proposal, which I will discuss later. At 64 m, a working platform of 24 m by 50 m is possible.

Animals do most of the work

This is a key factor in understanding the logic of the proposal. The proposed 64-metre level represents the point below which 80% of the volume of the pyramid had been placed—only 20% of the volume of the pyramid is above it. This statistic was pointed out by John Romer and is an important factor.6 This means that the bulk of the building’s stone can be carted close to the placement area by animals. Humans are needed only for the final positioning.

No grunting, heaving Egyptians would be needed, as shown in many cartoons.

Oxen can haul the massive 60-tonne stones that are found above the King’s chamber. No grunting, heaving Egyptians would be needed, as shown in many cartoons. The animals can also deliver all the stones for the remaining height to this last working platform at the 64-metre level.

The casing stones

An estimated 144,000 limestone casing stones up to 2.4 m thick covered the entire surface of the Great Pyramid to form a continuous smooth polished surface. These casing stones are so precise in placement and jointing that no penetration of the surface was made for 3,000 years. The first recorded modern entry was Al Mamun, the Cairo Caliph who tunneled an entry in AD 832.

The Greek historian Herodotus wrote of a large ramp on the east side. Indeed evidence has been found for the causeway on the eastern side. However, I suggest that this east-side ramp was not the main ramp for building the Pyramid. It is more likely that this ramp was at the end of the delivery road from the harbour to the Pyramid site for the casing stones. These are proven to have come from the other side of the Nile.7 At a later time the east-side ramp may have been utilized as a processional ramp—hence the remains. Herodotus says that this ramp was 10 years in the making which seems a long time for such a modest structure. Ten years would be a better time frame for building a southern ramp for the main construction as proposed.

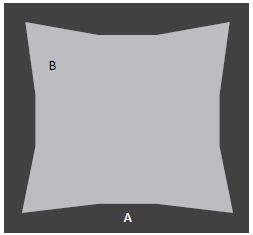

Figure 6. The core masonry of The Great Pyramid has a distinct hollowing, as much as 94 cm (37 inches) on the north face. It is not normally observable and can only be seen when special lines of sight are taken. In the above illustration (after Tompkins, ref. 7, p. 110), the hollowing of the core masonry is greatly exaggerated to show the effect. A. Pyramid base as actually built. B. Base of core masonry.

Building the courses

The evidence of the few casing stones found at the base of the pyramid is that these stones provided a polished accurate slope face that dovetailed into the course behind. Another subtle feature is that these stones were laid with a slight indent to the face resulting in a ‘crease’—called the apothem—at the centre of each face (figure 6). This fact was discovered by an early aerial photograph by English airman P. Groves in 1940 where shadows picked up the subtle indentation.8

This deviation in the stonework makes sense as it enables accurate checking by sight lines from corner to corner for each course.

The perimeter casing stone course was also rigid with a thin bed of mortar found to join each stone. This course was accurately aligned to control the geometry of the shape. The stones were leveled very accurately to the horizontal which then provided the gauge for the infill stonework behind. With this technique, once the perimeter course is in place it acts as a safety barrier and datum allowing for the rapid infill of the inner core. Work can also be done in different parts of the course level at the same time.

Another factor with working on one course at a time is that portable shade structures can be provided at any part of the building site enabling work to progress in hot conditions for the whole of the year.

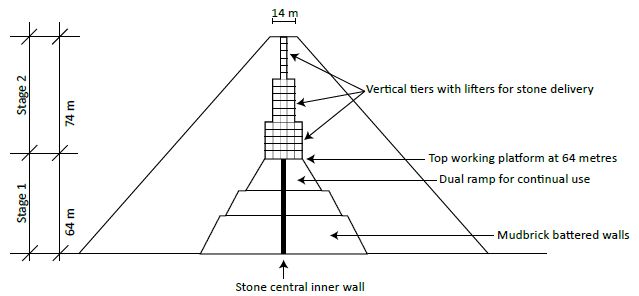

Tiers to the top—stage 2

Figure 7. Southern elevation of the Great Pyramid showing the construction ramp with mud brick battered walls at its maximum height.

Figure 8. Variation of the block thickness for each layer of the Great Pyramid from its base to its present summit (after Romer, ref. 2, p. 367).

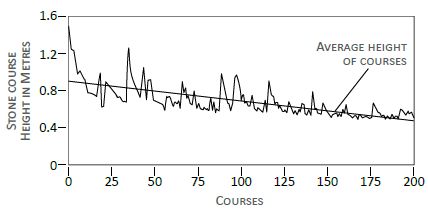

Above the 64-metre level a different approach would be required, as the size and slope of the ramp would have reached its maximum practicable level (figure 7). The remaining 20% of the blocks for the pyramid would now have to be placed in a steep structure for the rest of the height of 74 m (25 stories). It is important to note that above this level the stones become smaller and lighter (figure 8), which means they could be handled by a different construction technique.

The existing stepped courses of the Pyramid have ledges averaging about 600 mm in width and a height about 700 mm, resulting in an incline of about 51 degrees, which is very unworkable. Even with staggered scaffolding this can be dangerous.

Figure 9. Forming the vertical tiers, central south side only.

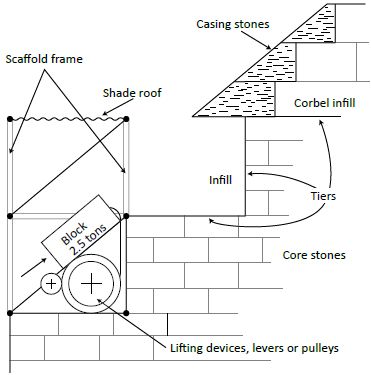

Figure 10. Lifting devices with the tiered layers.

Figure 11. Infill of the tiers and placement of the casing stones from the top down.

Therefore, it is proposed that on the southern side only, they created vertical ‘tiers’ with the core masonry with platforms of nominal dimensions 2.4 m wide and 2.8 m high (figure 9). This is a single-storey height that makes it easy for lifting blocks from one level to the next. It provides a safe working area for frames and scaffolds. On that level workers can have amenities, such as toilets, water supply and shade structures.

Lifter devices would be used on each of these level tiers to allow continual delivery of the stones. These lifters could be simple wooden or metal devices using the fulcrum and lever principle (figure 10). A number of prototypes have been developed to demonstrate this. Human operators can lift large stones above a small height. The lifting is only required for each single storey height which makes it safe. The stones could be packed in metal or timber frames for ease of handling. They would be lifted individually and transferred from lifter to lifter until they reached the required level. When they reached their destination working level they would be placed on adjustable metal rails and glided to the required position.

These tiers could be designed to have a number of vertical lifter hoists in a row allowing for multiple rates of delivery for stone. From a technical point of view these tiers could be corbelled to allow the infill stone to be bonded back into the structure on completion.9

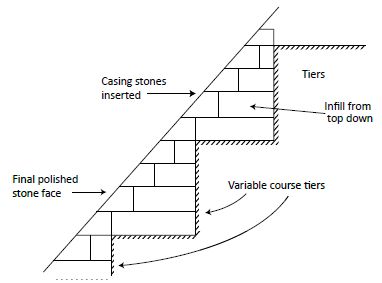

Finishing from the top down

I believe the current height of the pyramid is the same as the original, and a pyramidion (pointed capstone) was not constructed. In stage two, the pyramid structure is formed as at the lower levels with the casing stones first and the infill behind, but the vertical tiers in the centre of the southern side prevent the completion of all these courses. However, from the top it is possible to infill these courses from the top down (figure 11).

Once the top has been reached, the southern side tiers can be in-filled from the top down (figure 10). This requires matching courses of masonry and the casing stones placed level by level. No section is more than the nominal single storey (2.8m) in height, which is a safe working height.

A simple method of corbelling often used in masonry work enables the courses to be bonded in layer by layer as illustrated in figures 9, 10 and 11. The only difficulty is maintaining the precision of the casing stones which are placed after the core stones are inserted behind. However this insertion technique is only required over relatively short distances (e.g. 30–40 m) depending on the number of vertical lifters formed. The precision of the placement of the casing stones is illustrated on the adjacent Kafre pyramid where some of the stones are still in place (figure 12).

One of the unusual statistics on the dating of the pyramid is that some of the top mortar is dated as older than the bottom. The charcoal remains in some of the mortar tested by Haas gave a higher date reading in the 198th course compared to the 2nd course.10

When the level of the construction ramp is reached, the ramp is then dismantled layer by layer and the materials and the mud bricks recycled.

Building passages and chambers

wikimedia.org: Mirko ucur

Figure 12. The top of the adjacent Khafre Pyramid shows the remains of some casing stones still in place, which illustrate the smoothness of the finished face.

The subterranean passage beneath the pyramid (figure 5) was probably excavated below ground level at the time the base platform for the pyramid was prepared. With this two-stage proposal, all the other passages and chambers could have been formed as the stone blocks were placed into position and the work progressed. There are also the mysterious ‘star shafts’. These are a marvel in construction, as they penetrate through the core masonry as shown by the robotic exploration of Rudolf Gantenbrink.11 They would have been cut retrospectively with incredible accuracy.

There are several large chambers and a Grand Gallery. The cutting out and lining of these spaces would be done just below the work platform. This would allow plenty of light and air for workers, and also the ability to check all alignments which are very accurate. Lintels and ceiling stones would easily be placed in position once the 64-metre level for the stones was reached. Very little lifting would be required.

There has been some discussion that micro gravimetric measurements (X-rays) have shown lesser density in some corners and perimeter areas of the Pyramid.3 This may be due to different stone densities or cavities. If proven, these could be the remains of worker amenity areas in the course of the works. The ‘room’ recently rediscovered two thirds of the way up from the base in the north-east corner could be a supervision ‘office’ for northern and eastern sides.3

Why is every course different?

The exact measure of every course was first done by French surveyors and later followed by the British archaeologist Sir Flinders Petrie. Their range in dimensions is 500 mm to 1,500 mm (figure 8). This does not make sense from a construction point of view. Surely making every course the same would be quicker and simpler to build. An explanation can be found in the requirement for dimensional checking and knowing what number applies for each course. This is important in any internal cutting of passages.

By making every course different, the architect can easily know which level he is at for checking. A simple measure of a stone and checking with the referenced course index gives the position. With 209 courses, this is an important consideration.

Was Herodotus partly right?

A famous 5th century BC Greek historian Herodotus made several references to the building of the Great Pyramid.12 His source was Egyptian priests he visited at that time. He described a large ramp over 1.6 km long and a height of 15 m. This has been proposed as the eastern ramp by which Tura limestone for the casing stones was transported from the Nile harbour.

He also makes reference to the lifting machines which raised the stones from one level to the other. They are described as mechanical devices that were operated by humans on tiers. So both ‘ramps’ and ‘lifting machines’ seem to figure in the Egyptian explanation of the construction.

Conclusion

Tompkins said,

“Modern engineers are astounded by both the enormity of the problems involved in the construction of the Pyramid and the optician’s precision with which these problems were solved. As originally designed, with its full mantle of polished limestone, the Pyramid must have been a dazzling sight.”13

How was the Great Pyramid built? That is a question that has intrigued people for millennia. As these events took place in the past, and we have no observers or written illustrations of how the construction was achieved, it is not possible to ‘prove’ how an ancient structure was built. However modern architects and engineers can examine the structure and determine feasible methods that may have given the desired result. When we consider that the ancient people were as intelligent as we are and had access to a reasonable level of technology then certain solutions suggest themselves. We call it ‘constructability’—logic in building.

Many of the theories proposed do not have that logic—not possible or not practical. The dimensional aspects listed are also key in any proposal. However, the two stage solution for the construction of the Pyramid is a very feasible solution to how the Pyramids were built. It is clear that the builders of the Great Pyramid had obvious architectural and engineering skills. One thing is certain in the construction—it was meant to endure for a long time—which it has!

0 Comments:

Post a Comment